علم الكيمياء

علم الكيمياء

الكيمياء التحليلية

الكيمياء التحليلية

الكيمياء الحياتية

الكيمياء الحياتية

الكيمياء العضوية

الكيمياء العضوية

الكيمياء الفيزيائية

الكيمياء الفيزيائية

الكيمياء اللاعضوية

الكيمياء اللاعضوية

مواضيع اخرى في الكيمياء

مواضيع اخرى في الكيمياء

الكيمياء الصناعية

الكيمياء الصناعية |

Read More

Date: 6-9-2017

Date: 11-9-2017

Date: 3-9-2017

|

PERCHLORO- AND TRICHLOROETHYLENE

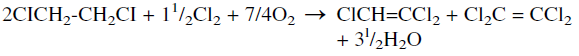

Perchloro- and trichloroethylenes could be produced from ethylene dichloride by an oxychlorination/oxyhydrochlorination process without by-product hydrogen chloride. A special catalyst is used:

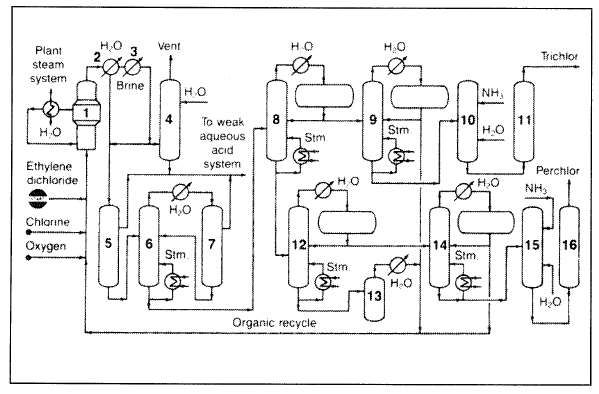

A fluid-bed reactor is used at moderate pressures at approximately 450°C. The reactor effluent, containing chlorinated organics, water, a small amount of HCl, carbon dioxide, and other impurities, is condensed in a water-cooled graphite exchanger, cooled in a refrigerated condenser, and then scrubbed. Separation of perchlor from the trichlor occurs by successive distillation. Figure 1.1 shows the PPG process

Figure 1.1. The PPG Industries Inc. Chloroethylene process for producing perchloro- and trichloroethylene: (1) reactor, (2) graphite exchanger, (3) refrigerated condenser, (4) scrubber, (5) phase separation of perchlor from trichlor, (6, 7) azeotropic distillation, (8) distillation train, (9–11) crude trichlor separation—purification, (10–16) crude perchlor separation—purification.

|

|

|

|

علامات بسيطة في جسدك قد تنذر بمرض "قاتل"

|

|

|

|

|

|

|

أول صور ثلاثية الأبعاد للغدة الزعترية البشرية

|

|

|

|

|

|

|

مكتبة أمّ البنين النسويّة تصدر العدد 212 من مجلّة رياض الزهراء (عليها السلام)

|

|

|