علم الكيمياء

علم الكيمياء

الكيمياء التحليلية

الكيمياء التحليلية

الكيمياء الحياتية

الكيمياء الحياتية

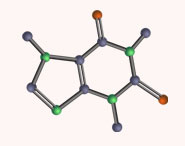

الكيمياء العضوية

الكيمياء العضوية

الكيمياء الفيزيائية

الكيمياء الفيزيائية

الكيمياء اللاعضوية

الكيمياء اللاعضوية

مواضيع اخرى في الكيمياء

مواضيع اخرى في الكيمياء

الكيمياء الصناعية

الكيمياء الصناعية |

Read More

Date: 26-5-2020

Date: 21-1-2016

Date: 29-9-2017

|

Properties and Uses of Epoxy Resins

Epoxy resins have a wide range of molecular weights (≈1,000–10,000). Those with higher molecular weights, termed phenoxy, are hydrolyzed to transparent resins that do not have the epoxide groups. These could be used in molding purposes, or crosslinked by diisocyanates or by cyclic anhydrides.

Important properties of epoxy resins include their ability to adhere strongly to metal surfaces, their resistance to chemicals, and their high dimensional stability. They can also withstand temperatures up to 500°C.

Epoxy resins with improved stress cracking properties can be made by using toughening agents, such as carboxyl-terminated butadiene-acrylonitrile liquid polymers. The carboxyl group reacts with the terminal epoxy ring to form an ester. The ester, with its pendant hydroxyl groups, reacts with the remaining epoxide rings, then more crosslinking occurs by forming ether linkages. This material is tougher than epoxy resins and suitable for encapsulating electrical units.

Major uses of epoxy resins are coatings for appliance finishes, auto primers, adhesive, and in coatings for cans and drums. Interior coatings of drums used for chemicals and solvents manifests its chemical resistance. In 1997, approximately 681 million pounds of unmodified epoxy resins were produced in the U.S.

|

|

|

|

تفوقت في الاختبار على الجميع.. فاكهة "خارقة" في عالم التغذية

|

|

|

|

|

|

|

أمين عام أوبك: النفط الخام والغاز الطبيعي "هبة من الله"

|

|

|

|

|

|

|

خدمات متعددة يقدمها قسم الشؤون الخدمية للزائرين

|

|

|