علم الكيمياء

علم الكيمياء

الكيمياء التحليلية

الكيمياء التحليلية

الكيمياء الحياتية

الكيمياء الحياتية

الكيمياء العضوية

الكيمياء العضوية

الكيمياء الفيزيائية

الكيمياء الفيزيائية

الكيمياء اللاعضوية

الكيمياء اللاعضوية

مواضيع اخرى في الكيمياء

مواضيع اخرى في الكيمياء

الكيمياء الصناعية

الكيمياء الصناعية |

Read More

Date: 18-8-2017

Date: 9-5-2016

Date: 7-8-2017

|

Steam Cracking Process

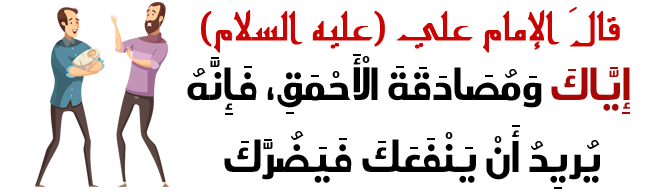

A typical ethane cracker has several identical pyrolysis furnaces in which fresh ethane feed and recycled ethane are cracked with steam as a diluent. Figure 1.1 is a block diagram for ethylene from ethane. The outlet temperature is usually in the 800°C range. The furnace effluent is quenched in a heat exchanger and further cooled by direct contact in a water quench tower where steam is condensed and recycled to the pyrolysis furnace. After the cracked gas is treated to remove acid gases, hydrogen and methane are separated from the pyrolysis products in the demethanizer. The effluent is then treated to remove acetylene, and ethylene is separated from ethane and heavier in the ethylene fractionator. The bottom fraction is separated in the deethanizer into ethane and C3fraction. Ethane is then recycled to the pyrolysis furnace.

Figure 1.1. Block diagram for producing ethylene from ethane.

An olefin plant that uses liquid feeds requires an additional pyrolysis furnace, an effluent quench exchanger, and a primary fractionator for fuel oil separation.

|

|

|

|

"إنقاص الوزن".. مشروب تقليدي قد يتفوق على حقن "أوزيمبيك"

|

|

|

|

|

|

|

الصين تحقق اختراقا بطائرة مسيرة مزودة بالذكاء الاصطناعي

|

|

|

|

|

|

|

قسم شؤون المعارف ووفد من جامعة البصرة يبحثان سبل تعزيز التعاون المشترك

|

|

|