علم الكيمياء

علم الكيمياء

الكيمياء التحليلية

الكيمياء التحليلية

الكيمياء الحياتية

الكيمياء الحياتية

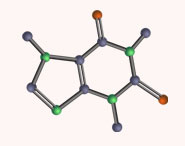

الكيمياء العضوية

الكيمياء العضوية

الكيمياء الفيزيائية

الكيمياء الفيزيائية

الكيمياء اللاعضوية

الكيمياء اللاعضوية

مواضيع اخرى في الكيمياء

مواضيع اخرى في الكيمياء

الكيمياء الصناعية

الكيمياء الصناعية |

Read More

Date: 6-8-2017

Date: 11-9-2017

Date: 22-8-2017

|

Delayed Coking

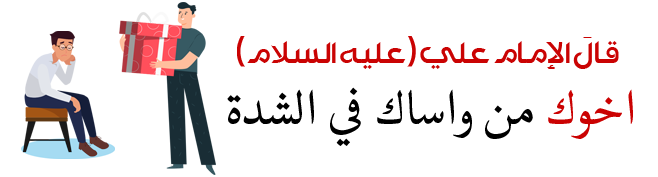

In delayed coking, the reactor system consists of a short contact time heater coupled to a large drum in which the preheated feed “soaks” on a batch basis. Coke gradually forms in the drum. A delayed coking unit has at least a pair of drums. When the coke reaches a predetermined level in one drum, flow is diverted to the other so that the process is continuous. Vapors from the top of the drum are directed to the fractionator where they are separated into gases, naphtha, kerosine, and gas oil. Table 1-1 shows products from a delayed coker using different feeds.

Table 1-1: Feeds and products from a delayed coker unit (using different feeds)

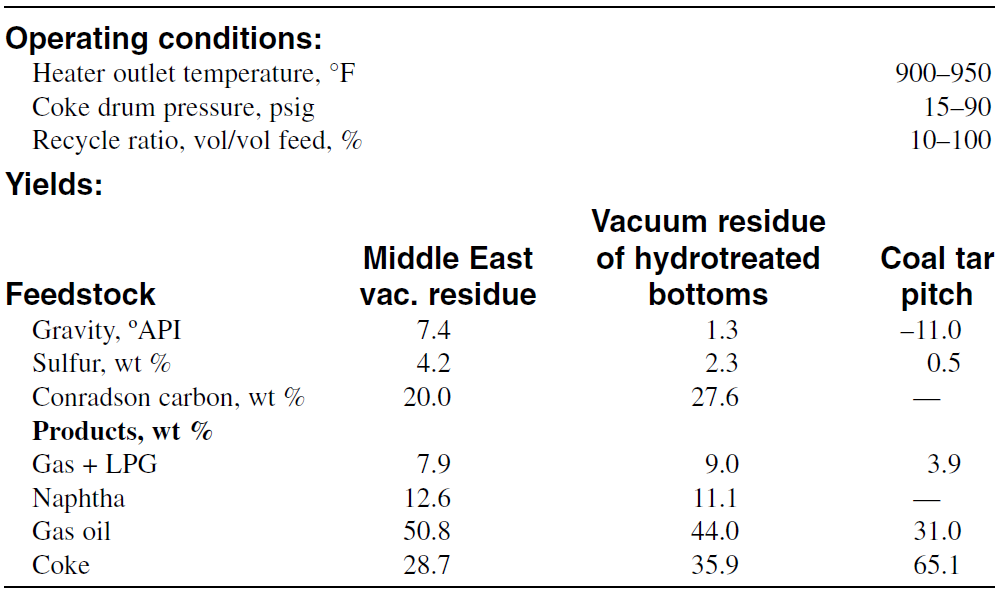

Decoking the filled drum can be accomplished by a hydraulic system using several water jets under at least 3,000 pounds per square inch gauge. Operating conditions for delayed coking are 25–30 psi at 480–500°C, with a recycle ratio of about 0.25 based on equivalent feed. Improved liquid yields could be obtained by operating at lower pressures. Coking at approximately 15 psi with ultra low recycle produced about 10% more gas oil. Operating at too-low temperature produces soft spongy coke. On the other hand, operating at a higher temperature produces more coke and gas but less liquid products. Mochida et al. reviewed the chemistry and different options for the production of delayed coke. It is the chemistry of the pyrolysis system which controls the properties of the semi and final coke structure. Factors that govern the reactions are the coke drum size, the heating rate, the soak time, the pressure, and the final reaction temperature. However, if everything is equal (temperature, pressure, soak time, etc.), the quality of coke produced by delayed coking is primarily a function of the feed quality. Figure 1-1 shows a delayed coking unit.

Figure 1-1. Flow diagram of a delayed coking unit:5 (1) coker fractionator, (2) oker heater, (3) coke drum, (4) vapor recovery column.

Coke produced from delayed coking is described as delayed sponge, shot, or needle coke depending on its physical structure. Shot coke is the most common when running the unit under severe conditions with sour crude residues. Needle coke is produced from selected aromatic feedstocks. Sponge coke is more porous and has a high surface area. The properties and markets for petroleum cokes have been reviewed by Dymond.

|

|

|

|

علامات بسيطة في جسدك قد تنذر بمرض "قاتل"

|

|

|

|

|

|

|

أول صور ثلاثية الأبعاد للغدة الزعترية البشرية

|

|

|

|

|

|

|

مكتبة أمّ البنين النسويّة تصدر العدد 212 من مجلّة رياض الزهراء (عليها السلام)

|

|

|