علم الكيمياء

علم الكيمياء

الكيمياء التحليلية

الكيمياء التحليلية

الكيمياء الحياتية

الكيمياء الحياتية

الكيمياء العضوية

الكيمياء العضوية

الكيمياء الفيزيائية

الكيمياء الفيزيائية

الكيمياء اللاعضوية

الكيمياء اللاعضوية

مواضيع اخرى في الكيمياء

مواضيع اخرى في الكيمياء

الكيمياء الصناعية

الكيمياء الصناعية |

Read More

Date: 22-12-2015

Date: 8-8-2017

Date: 7-8-2017

|

OLIGOMERIZATION OF BUTENES 248

2-Butenes (after separation of l-butene) can be oligomerized in the liquid phase on a heterogeneous catalyst system to yield mainly C8 and Cl2 olefins. The reaction is exothermic, and requires a multitubular carbon steel reactor. The exothermic heat is absorbed by water circulating around the reactor shell. Either a single- or a two-stage system is used.

The process can be made to produce either more linear or more branched oligomers. Linear oligomers are used to produce nonyl alcohols for plasticizers, alkyl phenols for surfactants, and tridecyl alcohols for detergent intermediates. Branched oligomers are valuable gasoline components. Figure 1.1 shows the Octol oligomerization process.

Figure 1.1. The Octol Oligomerization process for producing C8’s and C12’s and C16’s olefins from n-butenes: (1) multitubular reactor, (2) debutanizer column, (3) fractionation tower.

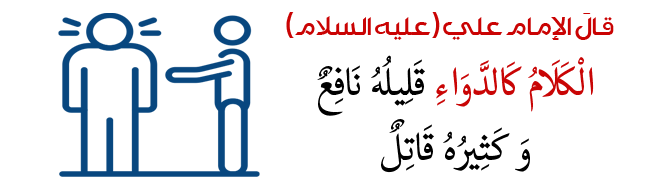

A typical analysis of A-type oligomers (branched) is shown in Table 1.1.

Table 1.1: Typical analysis of branched oligomers (Type A)

|

|

|

|

التوتر والسرطان.. علماء يحذرون من "صلة خطيرة"

|

|

|

|

|

|

|

مرآة السيارة: مدى دقة عكسها للصورة الصحيحة

|

|

|

|

|

|

|

نحو شراكة وطنية متكاملة.. الأمين العام للعتبة الحسينية يبحث مع وكيل وزارة الخارجية آفاق التعاون المؤسسي

|

|

|