النبات

مواضيع عامة في علم النبات

الجذور - السيقان - الأوراق

النباتات الوعائية واللاوعائية

البذور (مغطاة البذور - عاريات البذور)

الطحالب

النباتات الطبية

الحيوان

مواضيع عامة في علم الحيوان

علم التشريح

التنوع الإحيائي

البايلوجيا الخلوية

الأحياء المجهرية

البكتيريا

الفطريات

الطفيليات

الفايروسات

علم الأمراض

الاورام

الامراض الوراثية

الامراض المناعية

الامراض المدارية

اضطرابات الدورة الدموية

مواضيع عامة في علم الامراض

الحشرات

التقانة الإحيائية

مواضيع عامة في التقانة الإحيائية

التقنية الحيوية المكروبية

التقنية الحيوية والميكروبات

الفعاليات الحيوية

وراثة الاحياء المجهرية

تصنيف الاحياء المجهرية

الاحياء المجهرية في الطبيعة

أيض الاجهاد

التقنية الحيوية والبيئة

التقنية الحيوية والطب

التقنية الحيوية والزراعة

التقنية الحيوية والصناعة

التقنية الحيوية والطاقة

البحار والطحالب الصغيرة

عزل البروتين

هندسة الجينات

التقنية الحياتية النانوية

مفاهيم التقنية الحيوية النانوية

التراكيب النانوية والمجاهر المستخدمة في رؤيتها

تصنيع وتخليق المواد النانوية

تطبيقات التقنية النانوية والحيوية النانوية

الرقائق والمتحسسات الحيوية

المصفوفات المجهرية وحاسوب الدنا

اللقاحات

البيئة والتلوث

علم الأجنة

اعضاء التكاثر وتشكل الاعراس

الاخصاب

التشطر

العصيبة وتشكل الجسيدات

تشكل اللواحق الجنينية

تكون المعيدة وظهور الطبقات الجنينية

مقدمة لعلم الاجنة

الأحياء الجزيئي

مواضيع عامة في الاحياء الجزيئي

علم وظائف الأعضاء

الغدد

مواضيع عامة في الغدد

الغدد الصم و هرموناتها

الجسم تحت السريري

الغدة النخامية

الغدة الكظرية

الغدة التناسلية

الغدة الدرقية والجار الدرقية

الغدة البنكرياسية

الغدة الصنوبرية

مواضيع عامة في علم وظائف الاعضاء

الخلية الحيوانية

الجهاز العصبي

أعضاء الحس

الجهاز العضلي

السوائل الجسمية

الجهاز الدوري والليمف

الجهاز التنفسي

الجهاز الهضمي

الجهاز البولي

المضادات الميكروبية

مواضيع عامة في المضادات الميكروبية

مضادات البكتيريا

مضادات الفطريات

مضادات الطفيليات

مضادات الفايروسات

علم الخلية

الوراثة

الأحياء العامة

المناعة

التحليلات المرضية

الكيمياء الحيوية

مواضيع متنوعة أخرى

الانزيمات

Adsorption Method of Immobilisation

المؤلف:

John M Walker and Ralph Rapley

المصدر:

Molecular Biology and Biotechnology 5th Edition

الجزء والصفحة:

8-1-2021

2403

Adsorption Method of Immobilisation

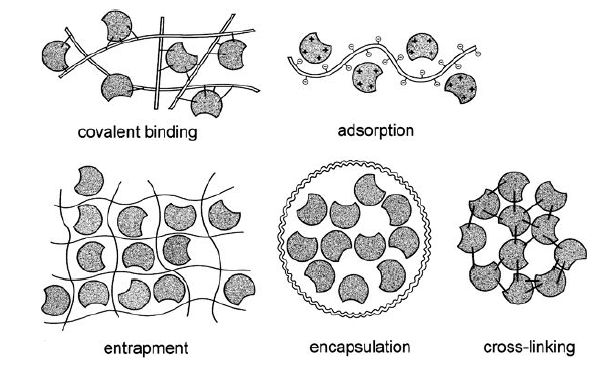

Immobilisation by adsorption is the simplest method and involves reversible non-covalent interactions between biocatalyst and support material (Figure 1).The forces involved are mostly weak electrostatic such as van der Waals forces and ionic and hydrogen bonding interactions, although hydrophobic bonding can be significant. These forces are individually very weak, but sufficiently large in number to provide good binding. For example, it is known that yeast cells have a surface chemistry that is substantially negatively charged so that use of a positively charged support material will allow immobilisation. Existing surface chemistry on a biocatalyst and on a support is utilised for adsorption, so no chemical activation or modification of support is required and little damage is inflicted on biocatalysts in this method of immobilisation.

Figure 1. Principal methods of biocatalyst immobilisation.

The procedure consists of mixing together biocatalyst and support under suitable conditions of pH, ionic strength, etc., for a period of incubation, followed by collection of immobilised biocatalyst and extensive washing to remove non-bound biocatalyst.

Advantages:

- little or no damage to a biocatalyst;

- simple, cheap and quick to obtain immobilisation;

- no chemical changes required for support or biocatalyst;

- easily reversed to allow regeneration with fresh biocatalyst.

Disadvantages:

- leakage of biocatalyst from support/contamination of product;

- non-specific binding of other material to the support;

- overloading of a support with biocatalyst;

- steric hindrance of a biocatalyst by a support.

The most significant disadvantage is leakage or desorption of a biocatalyst from support material. This can occur under circumstances such as environmental changes in pH, temperature and ionic strength. Sometimes a firmly adsorbed enzyme is readily desorbed during reaction as a result of substrate binding, binding of contaminants present in the substrate, product production or other condition leading to change in conformation (molecular shape) of the adsorbed enzyme.

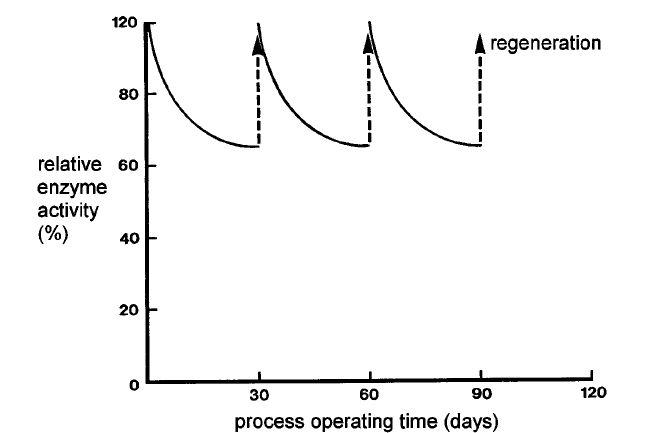

Physical characteristics of bioreactors such as flow rate, bubble agitation, particle–particle abrasion and scouring effect of particulate materials on reactor vessel walls can lead to desorption.Desorption can be turned to advantage if regeneration of support is built into the operational regime to allow rapid expulsion of ‘exhausted’ biocatalyst and replacement with fresh biocatalyst. In some commercial biotransformations, the economics of a process require the use of crude substrates containing contaminants that ‘poison’ the biocatalyst and so regular regeneration of biocatalyst is an essential part of the operation (Figure 2).

Non-specific binding can become a problem if substrate, product andor residual contaminants possess charges that allow interaction with a support material. This can lead to diffusion limitations and reaction kinetics problems, with consequent alteration in enzyme kinetic parameters . Further, binding of hydrogen ions to a support material can result in an altered pH microenvironment around a support with a consequent shift in pH optimum (1–2pH units) of a biocatalyst, and this may be detrimental to enzymes with precise pH requirements. Unless carefully controlled, overloading a support with excess biocatalyst can lead to low catalytic activity and in some circumstances a spacer molecule situated between an enzyme molecule and a support may be required to overcome problems of steric hindrance .

Figure 2. Graph showing the steady loss of immobilised enzyme with time and regeneration of activity at monthly intervals by addition of fresh enzyme.

الاكثر قراءة في الانزيمات

الاكثر قراءة في الانزيمات

اخر الاخبار

اخر الاخبار

اخبار العتبة العباسية المقدسة

الآخبار الصحية

قسم الشؤون الفكرية يصدر كتاباً يوثق تاريخ السدانة في العتبة العباسية المقدسة

قسم الشؤون الفكرية يصدر كتاباً يوثق تاريخ السدانة في العتبة العباسية المقدسة "المهمة".. إصدار قصصي يوثّق القصص الفائزة في مسابقة فتوى الدفاع المقدسة للقصة القصيرة

"المهمة".. إصدار قصصي يوثّق القصص الفائزة في مسابقة فتوى الدفاع المقدسة للقصة القصيرة (نوافذ).. إصدار أدبي يوثق القصص الفائزة في مسابقة الإمام العسكري (عليه السلام)

(نوافذ).. إصدار أدبي يوثق القصص الفائزة في مسابقة الإمام العسكري (عليه السلام)