النبات

النبات

الحيوان

الحيوان

الأحياء المجهرية

الأحياء المجهرية

علم الأمراض

علم الأمراض

التقانة الإحيائية

التقانة الإحيائية

التقنية الحيوية المكروبية

التقنية الحيوية المكروبية

التقنية الحياتية النانوية

التقنية الحياتية النانوية

علم الأجنة

علم الأجنة

الأحياء الجزيئي

الأحياء الجزيئي

علم وظائف الأعضاء

علم وظائف الأعضاء

الغدد

الغدد

المضادات الحيوية

المضادات الحيوية|

Read More

Date: 8-1-2021

Date: 9-1-2021

Date: 9-1-2021

|

Immobilisation

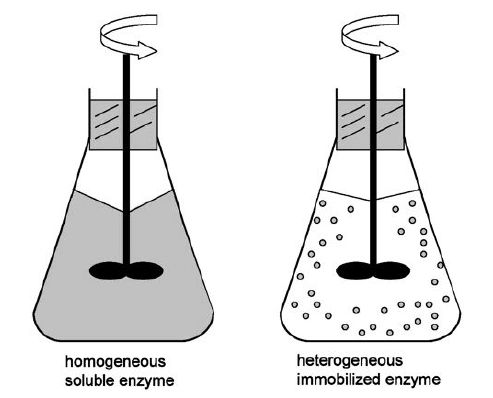

In a solution, biocatalysts behave as any other solute in that they are readily dispersed in solution or solvent and have complete freedom of movement in solution (Figure 1 ). Immobilisation may be viewed as a procedure specifically designed to limit freedom of movement of a biocatalyst. Immobilisation normally involves attachment of biocatalyst to or location within, an insoluble support material. In effect, a biocatalyst is separated from the bulk of the solution to create a heterogeneous two-phase system (Figure 1 ). Immobilisation provides three basic advantages over soluble-based systems:

- repeated use of the biocatalyst in batch reactions;

- simple separation of biocatalyst from product after reaction;

- continuous use of a biocatalyst in a suitable reactor system.

An immobilised biocatalyst is easily recovered after a batch reaction and this facility allows repeated use of the biocatalyst in a fresh batch.

Figure 1. Diagram showing how immobilisation separates a biocatalyst from the bulk solution phase to produce a heterogeneous two-phase mixture.

This advantage can improve the commercial viability of a reaction process that was previously too expensive in terms of biocatalyst costs.

Removal of biocatalyst from a product solution after reaction is complete means that the final product is not contaminated with biocatalyst and fewer expensive extraction procedures are required in finishing steps. Immobilisation of a biocatalyst will increase the options for bioreactor selection. An immobilised biocatalyst can be incorporated into cylindrical flow-through columns or other devices to produce continuous bioreactors in which a continuous flow of substrate enters at one end of the bioreactor and a continuous flow of product emerges from the other end. Such systems can operate continuously for weeks or months.

Recent expansion of biotechnology and expected developments that will accrue from advances in genetic technology have stimulated enthusiasm for immobilisation of biocatalysts.Research and development work has provided an extensive array of support materials and methods for biocatalyst immobilisation and much of the new immobilisation may be attributed to specific improvements for given applications rather than a concerted attempt to build a set of industrial

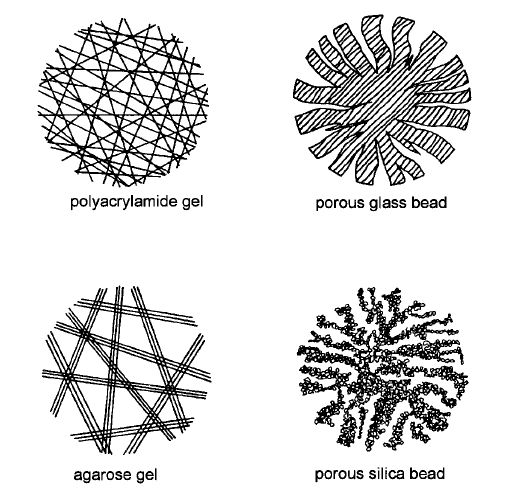

standards for immobilisation methodology. Consequently, there have been few detailed and comprehensive comparative studies on immobilisation methods and supports. Therefore, no ideal support material or method of immobilisation has emerged to provide a standard for a given type of immobilisation. Some work using functionalised mesoporous silica with open pores has extended the understanding of enzyme behaviour in an entrapment model and has contributed to the design of confining matrices to optimise the catalytic process by developing a model that accounts for the influence of a matrix environment on concentration effects, catalytic activity, turnover, structural integrity, enzyme denaturation/renaturation cycles and solvent effects.

Selection of support material and method of immobilisation is made by weighing the various characteristics and required features of a biocatalyst application against the properties/limitations/characteristics of a combined immobilisation/support (Figure 2). A number of practical aspects should be considered before embarking on experimental work to ensure that the final immobilised biocatalyst is fit for a planned application and will operate with optimum effectiveness.

Figure 2. Microstructure of some popular support materials.

|

|

|

|

التوتر والسرطان.. علماء يحذرون من "صلة خطيرة"

|

|

|

|

|

|

|

مرآة السيارة: مدى دقة عكسها للصورة الصحيحة

|

|

|

|

|

|

|

نحو شراكة وطنية متكاملة.. الأمين العام للعتبة الحسينية يبحث مع وكيل وزارة الخارجية آفاق التعاون المؤسسي

|

|

|