تاريخ الفيزياء

علماء الفيزياء

الفيزياء الكلاسيكية

الميكانيك

الديناميكا الحرارية

الكهربائية والمغناطيسية

الكهربائية

المغناطيسية

الكهرومغناطيسية

علم البصريات

تاريخ علم البصريات

الضوء

مواضيع عامة في علم البصريات

الصوت

الفيزياء الحديثة

النظرية النسبية

النظرية النسبية الخاصة

النظرية النسبية العامة

مواضيع عامة في النظرية النسبية

ميكانيكا الكم

الفيزياء الذرية

الفيزياء الجزيئية

الفيزياء النووية

مواضيع عامة في الفيزياء النووية

النشاط الاشعاعي

فيزياء الحالة الصلبة

الموصلات

أشباه الموصلات

العوازل

مواضيع عامة في الفيزياء الصلبة

فيزياء الجوامد

الليزر

أنواع الليزر

بعض تطبيقات الليزر

مواضيع عامة في الليزر

علم الفلك

تاريخ وعلماء علم الفلك

الثقوب السوداء

المجموعة الشمسية

الشمس

كوكب عطارد

كوكب الزهرة

كوكب الأرض

كوكب المريخ

كوكب المشتري

كوكب زحل

كوكب أورانوس

كوكب نبتون

كوكب بلوتو

القمر

كواكب ومواضيع اخرى

مواضيع عامة في علم الفلك

النجوم

البلازما

الألكترونيات

خواص المادة

الطاقة البديلة

الطاقة الشمسية

مواضيع عامة في الطاقة البديلة

المد والجزر

فيزياء الجسيمات

الفيزياء والعلوم الأخرى

الفيزياء الكيميائية

الفيزياء الرياضية

الفيزياء الحيوية

الفيزياء العامة

مواضيع عامة في الفيزياء

تجارب فيزيائية

مصطلحات وتعاريف فيزيائية

وحدات القياس الفيزيائية

طرائف الفيزياء

مواضيع اخرى

NITROGEN LASER STRUCTURE

المؤلف:

Mark Csele

المصدر:

FUNDAMENTALS OF LIGHT SOURCES AND LASERS

الجزء والصفحة:

p265

24-3-2016

3102

NITROGEN LASER STRUCTURE

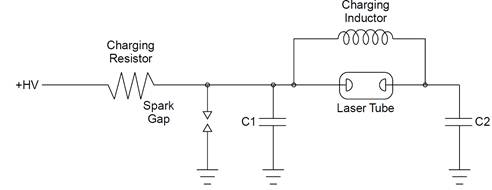

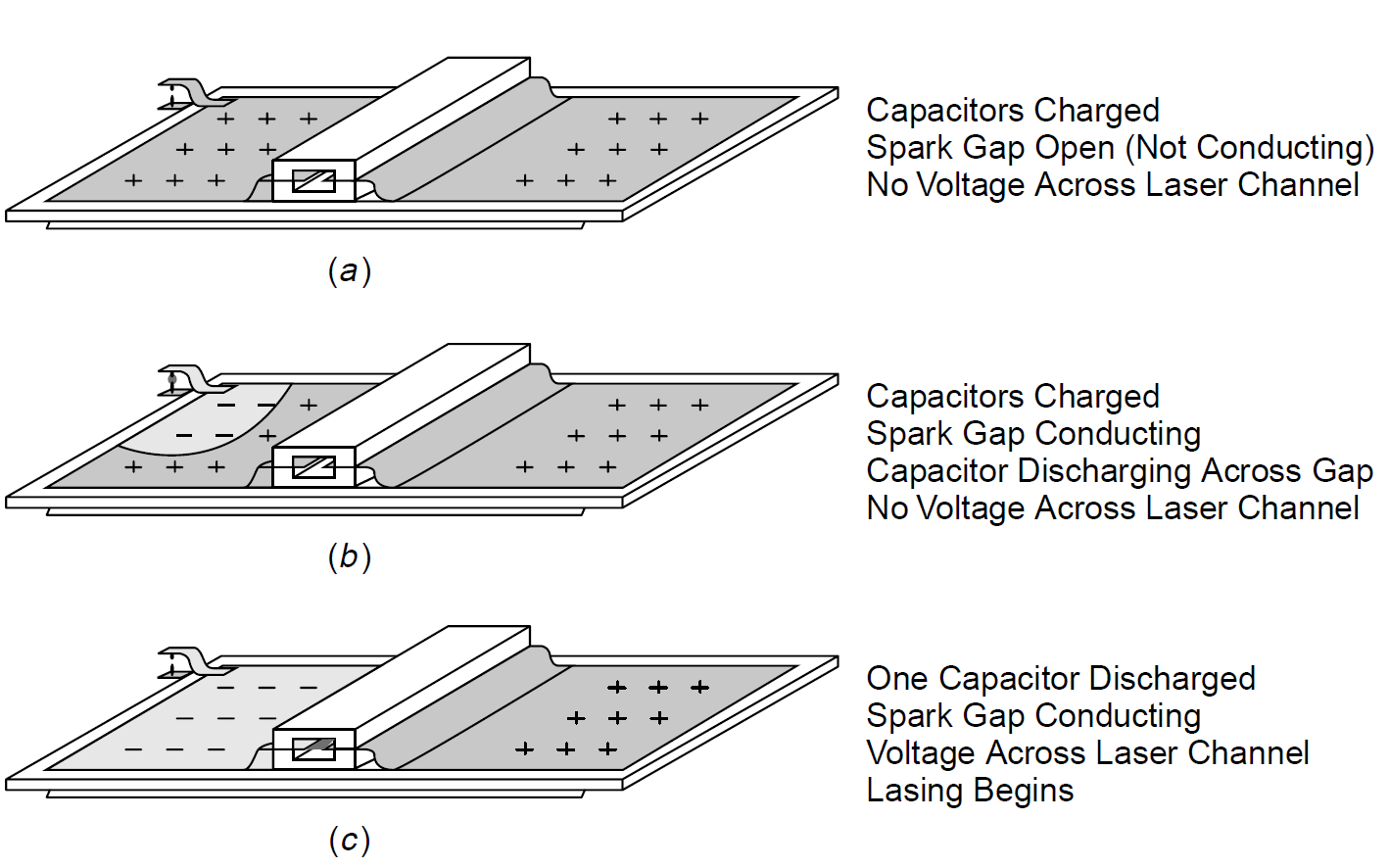

The basic requirement for a practical nitrogen laser is to supply a massive electrical current (i.e., a huge quantity of electrons) with a fast rise time and short pulse length to excite the gas. To achieve this, most nitrogen lasers use an electrical configuration called a Blumlein configuration, which generates a massive overvoltage of the laser channel (and subsequent large current through the lasing gas) with a rise time of nanoseconds. A Blumlein configuration is shown schematically in Figure 1.1, where we find two capacitors essentially in parallel separated by the laser channel itself. Both capacitors charge simultaneously through the charging inductor (which offers little electrical resistance to the charging current) until the spark gap fires when the breakdown voltage is reached (typically, about 15 kV for a small laser). In simplest form, a nitrogen laser may operate as a relaxation oscillator, repeatedly charging and firing; the use of triggered spark gaps or thyratrons allows the laser to be triggered as required. The gap now conducts essentially short-circuiting C1 and draining charge from it, making the top terminal of C1 negative. A massive voltage difference appears quite suddenly across the laser gap since the left side of the tube is now negative and the right side still positive. Charge from C2 flows across the laser channel as a pulse of very high electrical current, in many cases thousands of amperes.

The electrical dynamics of the laser are not as simple as a discharge, though, since the laser tube has long transverse electrodes over which the high current must be distributed. With a short discharge time necessitated by the short upper lasing level lifetime, the laser is best excited by a traveling electrical wave which starts at the rear of the laser and moves forward at the speed of light exciting nitrogen molecules as it progresses. To accomplish this, capacitors are fabricated as long, distributed capacitances parallel to the laser tube. The initiating spark gap is placed at

Figure 1.1. Electrical schematic of a Blumlein laser.

the rear of one capacitor so that the electrical pulse begins at the rear of the laser first and travels toward the front of the laser. In many cases it is possible to design the laser as a transmission line for efficient transfer of electrical energy into the lasing volume. The sequence of events during firing of the laser is outlined in Figure 1.2. In this particular design, common for small laboratory-type nitrogen lasers, the capacitors are fabricated on an epoxy glass substrate. Two capacitors are formed with copper foil on the top of the board (there is a separation between the two capacitors underneath the laser tube, so they are not visible in the figure), and the bottom of the board is the common terminal for both. The spark gap that initiates electrical discharge is mounted on the left capacitor near the rear of the laser.

In the simplified figure (in which details such as the charging inductor are omitted for clarity) both capacitors are charged to a high voltage equally, so no voltage difference appears across the laser channel. As the capacitors are charged, the voltage across the capacitors as well as the spark gap rises until breakdown occurs (in Figure 1.2b) and the spark gap conducts. Charge can be visualized in the figure as moving toward the spark gap in an arc centered around the spark gap. No voltage appears across the laser channel until the charge at the rear of the left capacitor for the laser has been drained and a voltage differential appears at the rear of the laser channel. The discharge in the laser thus begins here. As the traveling wave in the capacitor spreads, the voltage differential travels toward the front of the laser channel at the speed of light, generating a discharge that also travels toward the front of the laser. Light emission follows the discharge and a beam emerges from the laser.

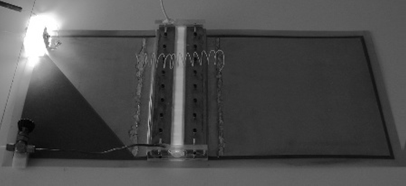

A practical nitrogen laser based on this design is seen operating in the author’s laboratory in Figure 1.3. The initiating spark gap is visible in the upper-left corner.

Figure 1.2. Nitrogen laser discharge sequence.

Figure 1.3. Practical nitrogen laser.

It emits an intense flash of light since high currents pass through it. As well as the gap, other visible features include the charging inductor, which bridges the laser tube and the charging resistor near the spark gap. This is a flowing-gas laser in which nitrogen gas under low pressure flows slowly through the tube. A needle valve used to regulate flow is also seen in the lower left of this laser. After initiation of laser action by the spark gap and discharge through the laser channel, the laser pulse is generated and will continue until population inversion ceases. Laser action ceases regardless of how long the electrical pulse lasts, so it is pointless to design a laser with a longer discharge time than this. This parameter determines the size of the capacitors employed in the laser.

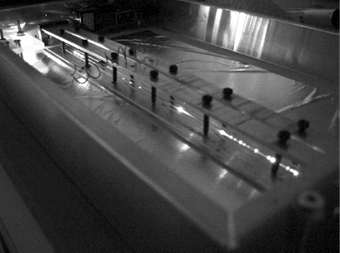

As well as operating at low pressures (generally, 20 to 60 torr), nitrogen lasers may operate at atmospheric pressure in a TEA configuration. These lasers are physically similar to the low-pressure types described in this chapter, and most use a Blumlein configuration. In the case of a TEA nitrogen laser, though, the lifetime of the ULL decreases to about 2.5 ns. The requirements for a fast discharge are even more pronounced in a TEA laser, which must be constructed to keep inductances in the discharge path to an absolute minimum. With this in mind, dielectrics for capacitors are kept very thin (since the intrinsic inductance of a transmission-line capacitor is proportional to the thickness of the dielectric) and the laser channel is mounted directly on top of the capacitors. A practical TEA laser is pictured in Figure 1.4, in which the spark gap is located in the upper-right corner of the photo and the long transverse electrodes are visible down the center of the laser.

The laser pictured operates using open air as the lasing gas. This is possible since air is 78% nitrogen, although output power decreased by 80% over the use of pure nitrogen gas. A possible source of inefficiency is evident in that the discharge reveals hot spots or arcs. Unlike the low-pressure laser, which features a consistent and even discharge between the electrodes, discharges in TEA lasers tend to concentrate and resemble individual sparks. For efficiency, measures must be taken to even out the discharge, including dilution of the nitrogen gas with helium, use of an electrode structure consisting of multiple points, and preionization of the discharge channel

Figure 1.4. TEA nitrogen laser.

with a high-voltage corona or ultraviolet radiation before the main laser discharge ensues.

Most small commercially available nitrogen lasers use spark gaps for their simplicity. These spark gaps are filled with nitrogen gas for reliable, predictable firing. In the case of a TEA laser, the gap may be placed inside the same pressure vessel as the rest of the laser. Filling with nitrogen also eliminates the objectionable production of ozone when the gap fires. In some larger lasers, thyratrons are used instead of spark gaps. Thyratrons are switching devices that use mercury vapor or hydrogen gas and feature incredibly fast rise times, many times faster than spark gaps. As well as faster switching times, thyratrons also allow triggering on command instead of simply triggering when the spark gap is overvoltaged, an important feature when this laser is used in a laboratory experiment requiring synchronization and precise timing.

Because of the low inductance discharge path required, essential elements of the nitrogen laser, such as storage capacitors and switches (thyratrons or spark gaps), are an integral part of the laser itself. To charge the capacitors, a basic high voltage supply is required, the supply current of this supply limiting the maximum firing rate for the laser. Designs for high-voltage power supplies vary from simple neon-sign transformers to efficient and compact switching power supplies. These supplies are usually housed in the main laser housing for safety.

In many low-pressure nitrogen lasers, gas flows continually through the lasing channel. This helps to eliminate impurities generated during the discharge as well as cool the laser. Gas flow is quite slow, so consumption is minimal. Many small commercial nitrogen lasers are of the TEA variety and use a sealed laser channel, so a gas supply and vacuum pump are not required, making a much simpler laser for laboratory use. With a fast enough discharge time, some low-pressure nitrogen lasers can also operate using hydrogen gas (with a transition in the extreme UV at 160 nm) or neon gas (with a visible transition at 540.1 nm). Both of these alternatives have shorter upper-level lifetimes than nitrogen does, so an extremely fast laser discharge is required (much faster than normally required in a nitrogen laser). Another alternative is the use of a carbon dioxide gas mixture consisting of helium, nitrogen, and carbon dioxide. With suitable optics the laser operates as a TEA laser, producing fast, short pulses of light at 10.6 μm in the infrared.

الاكثر قراءة في أنواع الليزر

الاكثر قراءة في أنواع الليزر

اخر الاخبار

اخر الاخبار

اخبار العتبة العباسية المقدسة

الآخبار الصحية

قسم الشؤون الفكرية يصدر كتاباً يوثق تاريخ السدانة في العتبة العباسية المقدسة

قسم الشؤون الفكرية يصدر كتاباً يوثق تاريخ السدانة في العتبة العباسية المقدسة "المهمة".. إصدار قصصي يوثّق القصص الفائزة في مسابقة فتوى الدفاع المقدسة للقصة القصيرة

"المهمة".. إصدار قصصي يوثّق القصص الفائزة في مسابقة فتوى الدفاع المقدسة للقصة القصيرة (نوافذ).. إصدار أدبي يوثق القصص الفائزة في مسابقة الإمام العسكري (عليه السلام)

(نوافذ).. إصدار أدبي يوثق القصص الفائزة في مسابقة الإمام العسكري (عليه السلام)